Description

The TS or Top Speed Black waxes are gliders for competition that work extremely well on dirty snow and when dry friction conditions exist.

TS5 BLACK, -10°C/-18°C, 40G

The 5 series is the hardest wax in the TSB line, and is a great choice in cold conditions (hint – great for New England), both for alpine and cross country. It is loved by servicemen, due to its great durability and properties when the snow is dirty. This is achieved thanks to the black solid lubricant additive that also reduces friction when very cold snow. Despite being a wax for cold conditions, the melting point makes it easier to apply than many competitors in this area, without sacrificing the great glide properties.

TS6 BLACK, -6°C/-12°C, 40G

The TS6B is the second hardest wax in the TSB line, and is a great choice in typical winter conditions, both for alpine and cross country. The speed of the iron should be approx. 8-10 sec. on a skating ski. The wax can be re-heated after cooling to room temperature (10 min) for better durability. Scraping after appr. one minute. Important to have a good iron to get an efficient melting of the wax. TS6B can be used as a race wax alone or as a base for top coats. Recommended iron temp.: 155°C (311°F).

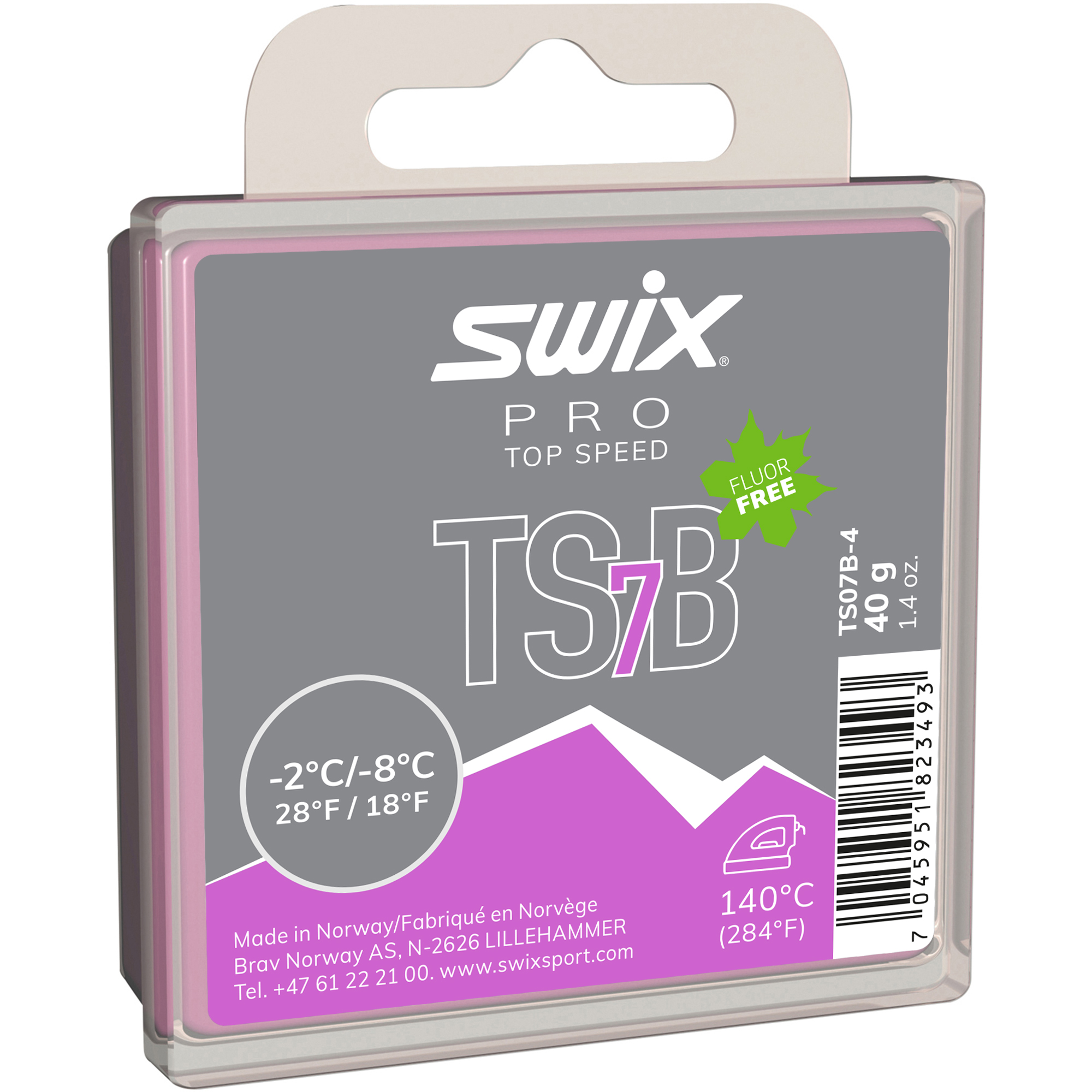

TS7 BLACK, -2°C/-8°C, 40G

TS7B is a versatile wax suited for normal winter conditions below the freezing point. Its hardness makes it convenient to work with and easy to get a good end-result. The solid lubricant additive reduces the friction in cold conditions and in contaminated snow. It’s a very popular wax both in alpine and cross country and has shown good properties on artificial snow in addition to natural, transformed older snow. The speed of the iron should be approx. 8-10 sec. on a skating or alpine ski. The wax can be re-heated after cooling to room temperature (10 min) for better durability. It’s important to have a good iron to get an efficient melting of the wax. TS7B can be used as race wax alone but is often used as base for top coats. Recommended iron temp: 150°C (302°F).

TS8 BLACK, -4°C/+4°C, 40G

TS8B is made harder than the std TS8. The adjusted hardness makes the wax more durable and absorbs less dirt. The solid lubricant additive reduces the friction in contaminated snow. Excellent results in artificial snow as well as natural transformed older snow, especially noticeable when used alone. The speed of the iron should be approx. 8-10 sec. on a skating or alpine ski. The wax can be re-heated after cooling to room temperature (10 min) for better durability. It’s important to have a good iron to get an efficient melting of the wax. TS8B can be used as race wax alone but is often used as a base for top coats. Recommended iron temp: 150°C (302°F).

TS10 BLACK, 0°C/+10°C, 40G

TS10B is made harder than the std. TS10, as the adjusted hardness makes the wax more durable and absorbs less dirt. The solid lubricant additive reduces the friction in contaminated snow. Excellent results in artificial snow as well as natural transformed older snow, especially noticeable when used alone. The speed of the iron should be approx. 8-10 sec. on a skating or alpine ski. The wax can be re-heated after cooling to room temperature (10 min) for better durability. Important to have a good iron to get an efficient melting of the wax. TS10B can be used as race wax alone, but is often used as a base for top coats. Recommended iron temp: 165°C (329°F).

Reviews

There are no reviews yet.