Description

3/4 length base layer designed to protect the body from objects that could cause lacerations to the skin, especially in the sensitive areas of the body. The development of these garments has been required by FIS in order to ensure the WC athletes have a higher safety in case of a fall. Knowing the needs of athletes we have developed a product that do not limit the movements and it is at the same time thermic, elastic and antibacterial.

Padding is removable.

Certification: CUT RESISTANCE 1 FIS Star, LEVEL 3 EN 388:2004 Energiapura continues its research and development of these products to give more safety to our sport.

In recent years the theme of safety on the track has gained the attention and importance it necessarily deserves.

There are many areas in which the need to protect, prevent and inform is clearly recognized and a risk that, when not calculated, can be the cause of the worst outcome.

The race world has always been seen as the center of development of the best solutions, where the research applied to the competition allows to reach the best performance, touching the limit of every element involved in the performance.

Alpine skiing testifies how many race tools were born from a need for protection: we think of helmets, gloves, back protectors or shin guards, all objects to which the laws of aerodynamics have been applied, of physics and mechanics to be able to earn even a few cents without ever losing in safety and reliability.

In this setting, the limits are not always the same, making it indispensable the continuous updating recognizing that the risks depend directly on this typical evolution of the physical and technological limit.

So here and in this precise context, the “personal impact protection devices” are fitted with the “cut” ones.

In detail we know how modern skiing has been able to stress every aspect related to performance, getting to treat the blades as real blades with cutting properties comparable to those of work tools dedicated to cutting and pure cutting. Sharpening and surface treatment processes that in the event of a fall once again raise the risk of injury with a dynamic already known and very similar to that of short track, hockey and long track skating. We are talking about serious injuries with severe consequences.

Personal cut protection devices which meet these requirements must of course be wearable, necessarily functional and necessarily effective.

Most of the time, we’re talking about tissue. Fabrics used for the construction of garments dedicated to military and hospital activities, fabrics that give rise to safety covers in construction contexts and even fabrics with many applications in the world of work.

It is a sector well protected by international regulations with standards that are the basis of the realization capabilities of every company involved in a production process of this kind.

The European reference standards are: EN 13998, EN 1082-2, EN 388:2016, while the American standards are: ASTM D – 276/’87, ASTM F 1671, ASTM 1342, ASTM 2878. Without going into the specifics of each single regulation we try to understand what are the rules that characterize an anti-cutting fabric.

The test methods of an anti-cutting fabric all involve the use of a blade defined in its geometry, weight, size and sharpening. The specificity of the cutting tests is such that a single cut is never expected, but a short wear cycle of the selected sample. Reporting these details of the evaluation process of an anti-cutting fabric, allows you to better frame the needs and needs of the world of sport.

Confirming our focus on alpine skiing, we can well understand how much more interesting and pertinent is the single cutting event rather than a repeated passage of a blade on the same point. A second observation to be made concerns the profile of a ski blade that can never be directly compared with that of a blade and therefore will never have the same cutting capacity.

The two variables that significantly influence the picture of the characteristics of an anti-shear fabric are: the impact pressure between the foil and the fabric and the relative speed between the ski and the athlete.

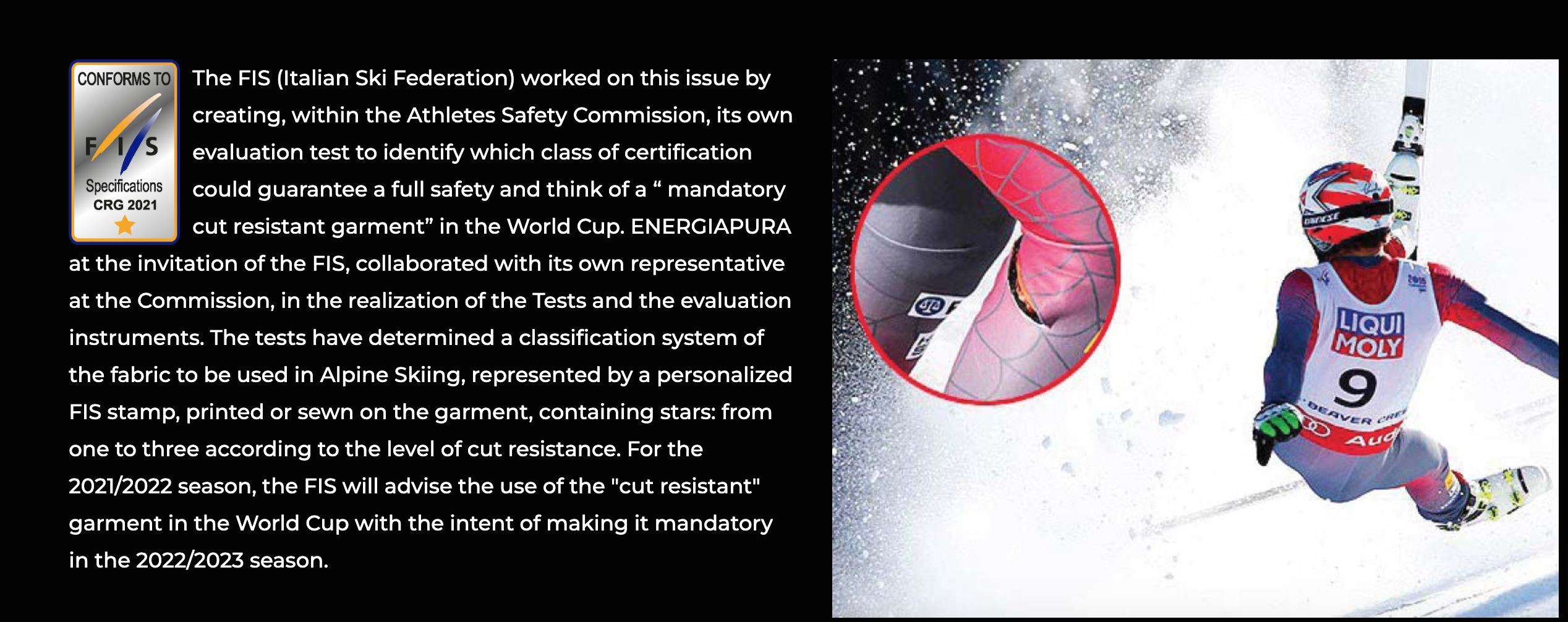

The FIS (Italian Ski Federation) worked on this issue by creating, within the Athletes Safety Commission, its own evaluation test to identify which class of certification could guarantee a full safety and think of a “ mandatory cut resistant garment” in the World Cup. ENERGIAPURA at the invitation of the FIS, collaborated with its own representative at the Commission, in the realization of the Tests and the evaluation instruments. The tests have determined a classification system of the fabric to be used in Alpine Skiing, represented by a personalized FIS stamp, printed or sewn on the garment, containing stars: from one to three according to the level of cut resistance. For the 2021/2022 season, the FIS will advise the use of the “cut resistant” garment in the World Cup with the intent of making it mandatory in the 2022/2023 season.

The report of cutting injuries is now on the agenda, moving from the less serious ones to those in which the risk of permanent damage for the athlete has been touched. It is not alarmism but a new and proven threat for our athletes: this is because it does not involve only the athlete of excellence but it is now a situation of real alarm even in the youth categories. In addition to the fall we also have a case study of cutting resulting in collision between skiers, both in the free field and in Parallel Slalom races.

Reviews

There are no reviews yet.